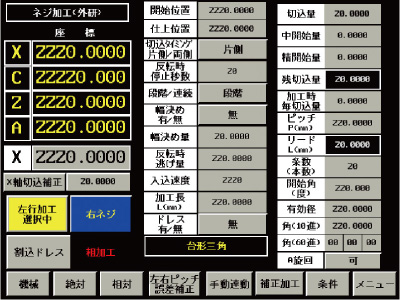

Simple operation

An operator only needs to input specifications according to a drawing for various types of thread grinding machining.

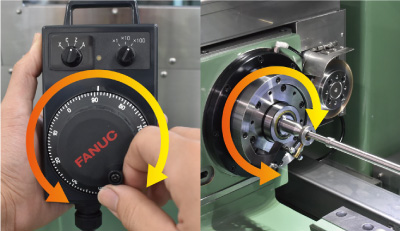

Positioning of workpieceand grinding wheel∗1

The pulse handle for positioning is equipped as a standard. The Workhead spindle and L/R axis operate in conjunction with the rotation of the pulse handle. Furthermore, semi-automatic function is also provided for easy positioning of tapered workpieces.

∗1: Synchronization function of workhead spindle and L/R axis by manual.

Operation image of synchronization of two axes.

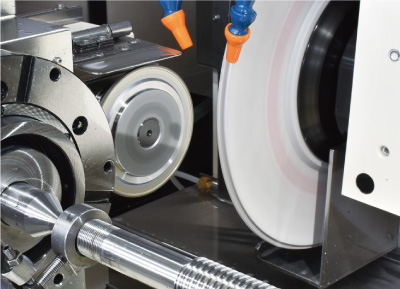

Corresponding to Various Machining

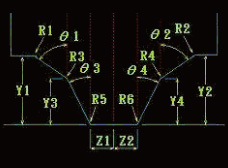

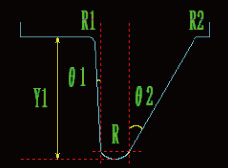

The rotary dress device behind the workhead spindle and our original grinding wheel-forming system enable various wheel shapes. The operator can set various shapes such as general standard screws, special shape screws, and ball screws with ease. Furthermore, our forming system corresponds to dress conditions that are suitable for rough and finish machining.

The Rotary dress device is mounted behind the workhead spindle.

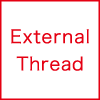

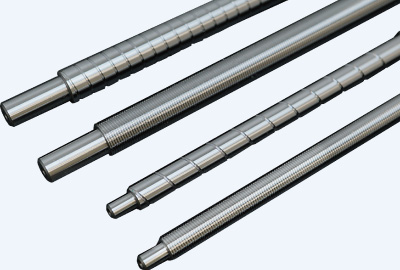

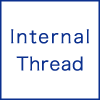

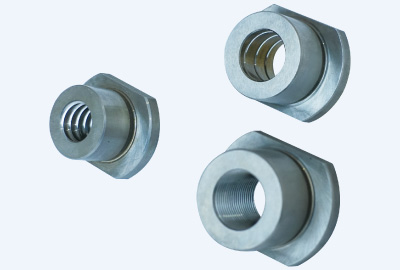

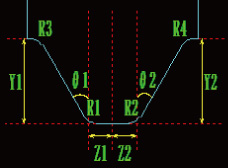

Formable Thread Shapes

Trapezoidal/Triangular shape

Polygonal shape

Buttress shape

Ball screw shape is also processable.

Formed Dresser is also mountable.

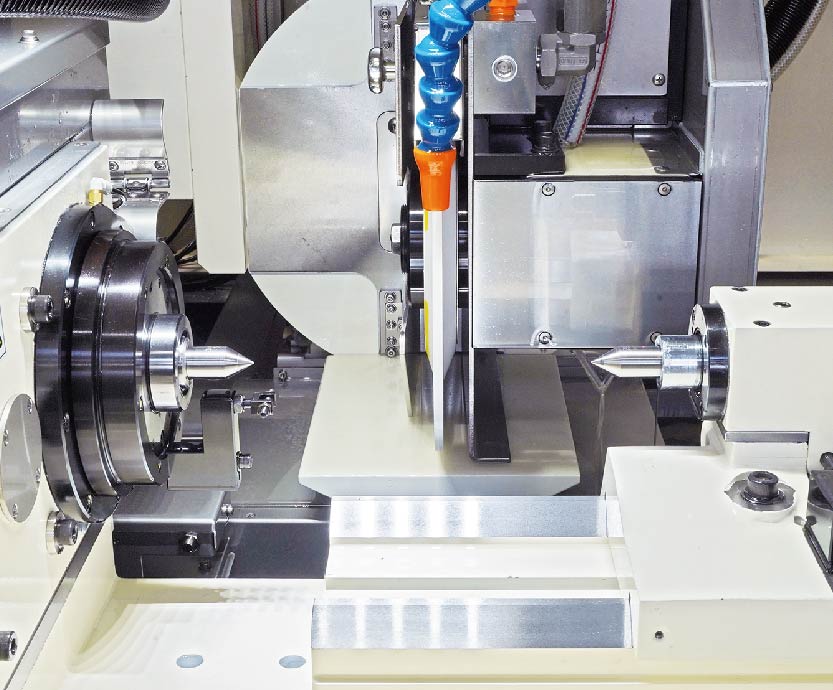

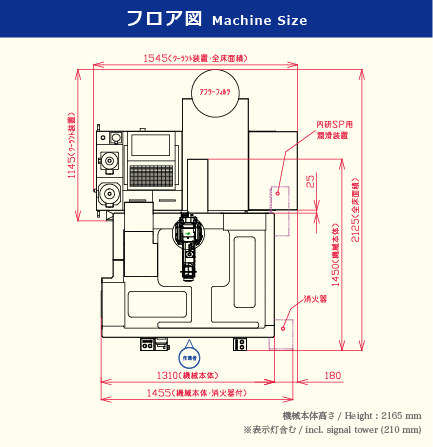

Compact Machine Body for Small workpieces

Specialized in small workpieces to achieve significant machine size reduction.

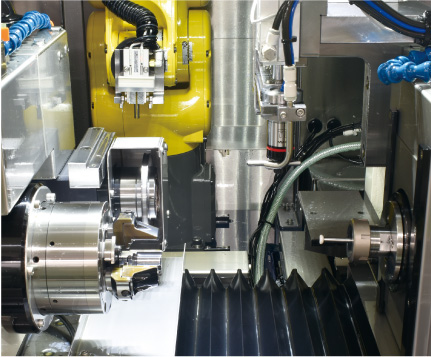

Mounting a work changing robot (OP) and a starting position detector (OP) enables continuous automatic machining.

Other Options

Scroll chuck

Steady rest

| Items | TO10-30 | TI10-10 | unit | |

|---|---|---|---|---|

| Capacity | Swing over table | 180 | 200 | ∅mm |

| Max. length of screw | 300 | 50 | mm | |

| Max. lead angle | Within max. tilt angle of grinding wheel | mm | ||

| Max. weight of workpiece | Cantilevered support | 4 | kg | |

| Grinding between centers | 5 | ― | kg | |

| Wheel axis | Wheel fixing method (max. shank dia.) | Original flange | Collet 30000 rpm (max.∅16) 60000 rpm (max.∅6) | ― |

| Wheel size (OD/ID/W) | ∅305 / 50.8 / 20 | ― | mm | |

| max. wheel speed | 3000 | 30000 / 60000 | rpm | |

| Spindle motor | 1.5 | 1.5 / 0.8 (30000 / 60000) | kW | |

| Max. tilt angle | ± 25 | ± 10 | deg. | |

| F/B axis | Feed amount | 240 | 135 | mm |

| Min. feed amount | 0.0001 | mm | ||

| Dressing device | Standard equipment | Diamond Rotary Dresser (OD ∅90) | ― | |

| L/R axis | Feed amount | 405 | 315 | mm |

| Min. feed amount | 0.0001 | mm | ||

| Workhead | Spindle speed | 0 ∼ 200 | rpm | |

| Min. indexing angle | 0.0001 | deg. | ||

| Center | MT No. 2 | ― | ― | |

| Scroll chuck | 4 | in. | ||

| Tailstock | Center | MT No. 2 | ― | ― |

| Capacity | Coolant device | 195 | ℓ | |

| Distance from bed to workpiece center | 1110 | mm | ||

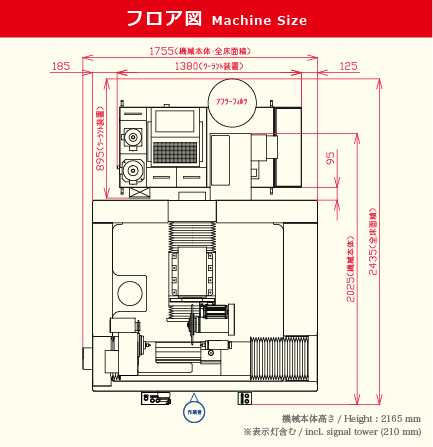

| Machine size (W/D/H) | 1755×2435×2165 | 1545×2125×2165 | mm | |

| Machine weight | 2500 | 2000 | kg | |

| Control | FANUC | ― | ||

| Power supply | AC 200V ±10% 50/60 | Hz | ||

| Control circuit power | DC 24 / AC 100 | V | ||

| Total amount of electricity | 24 | 14 | kVA | |

| The contents are subject to change without notice. | ||||