Surface Grinding

Cross pitch or traverse feed allows surface grinding. B/F reversing positions are easily set by teaching operation.

WAZA840-NC Splash guard + Rear splash guard

NAGASHIMA original structure

The workhead and column are integrally structured to enhance infeed accuracy and rigidity for heavy duty grinding.

Operator friendly CNC Machine

WAZAμ is equipped with a FANUC. High versatility and operability are achieved by combining the FANUC control with our original interactive software.

Increasing Operational Efficiency with a Simplified Operation Screen

WAZAµ's interactive screen is so simple. It changes the concept of CNC machine. Even an operator, who has never used CNC machine, can manage with ease. Machining conditions can be set up in one time to start automated operation.

"Handwheels" for High Performance CNC Machine

To overcome the image of "non-operator-friendly" of CNC machine, WAZAµ provides a versatile system, such as handwheels for both longitudinal and cross axes. Instantly switch over from CNC to versatile operation. This CNC machine even has high productivity in multikind small-lot production.

The Simple interactive Software

Standard Grinding Features

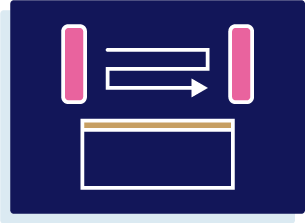

Surface Grinding

Cross pitch or traverse feed allows surface grinding. B/F reversing positions are easily set by teaching operation.

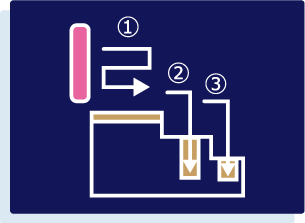

Program Grinding

Multiple surfaces and grooves are processed at one time.

Groove Grinding

Grooves of two different heights, depths, and pitches are processed at one time.

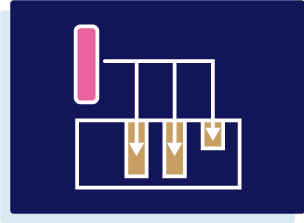

Contour Grinding

Shape input allows contour grinding. Three different shape programs (rough/medium/finish) can be set at one machining.

Dressing Devices ※1

Maintains grinding wheel shape automatically and constantly during machining

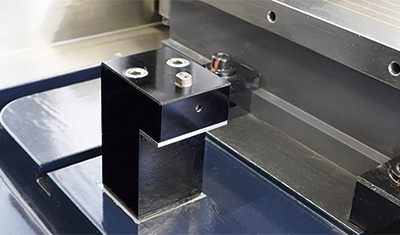

Point Dresser

Single point dresser enables automatic parallel dressing during machining. Automatic machining can be performed without concerning about grinding wheel dulling.

※It is a standard equipment when the dresing device is mounted.

Rotary Dresser

Rotary dresser enables forming of grinding wheels and automatic dressing during machining. Multiple grinding wheel shapes can be formed continuously.

※Optional

※1 The width of magnetic chuck is 100mm smaller with a dressing device.

| Items | Unit | Machine size | |||||

|---|---|---|---|---|---|---|---|

| 415 | 520 | 630 | 640 | 840 | |||

| Chuck size (without dressing device) | mm | 400×150 | 500×200 | 600×300 | 600×400 | 800×400 | |

| Chuck size (with dressing device) | mm | 300×150 | 400×200 | 500×300 | 500×400 | 700×400 | |

| Table surface to spindle center | mm | Max. 500 | |||||

| Max. travel | Up/Down (Y) | mm | 310 | ||||

| Back/Forward (Z) | mm | 195 | 245 | 340 | 440 | 440 | |

| Left/Right | mm | 550 | 650 | 850 | 850 | 950 | |

| Feed speed | Rapid (G00) | mm/min. | back/forward Max.1200 up/down Max.600 | ||||

| Grinding (G01) | mm/min. | back/forward Max.1200 up/down Max.600 | |||||

| Left/Right | mm/min. | 0 ∼ 25 | 0 ∼ 20 | ||||

| Least input increment | Up/Down (Y) | mm | 0.0001 | ||||

| Back/Forward (Z) | mm | 0.0001 | |||||

| Wheel size (OD/ID/W) | mm | ∅255/∅50.8/25 (OP:∅205/∅31.75/16) | ∅305/∅76.2/32 (OP:∅255/∅50.8/25) |

||||

| Taper (Max. dia×taper) | ∅33×1/6 (OP GW∅205→∅25×1/4) | ∅45×1/6 (OP GW∅255→∅33×1/6) |

|||||

| Wheel spindle speed (inverter) | rpm | 0∼3600 | |||||

| Wheel sindle motor | kW | 2.2 (4P) | 7.5 (4P) | ||||

| Control unit | FANUC | ||||||

| Machine weight | kg | 1600 | 2000 | 3500 | 3800 | 4000 | |

| Floor space (W/D) | mm | 2450×2390 | 2600×2450 | 3750×2760 | 3750×2850 | 3850×2850 | |

| Power consumption | kVA | 14 | 14 | 20 | 20 | 20 | |

| Standard equipment and functions ●: Standard equipment ■: Optional ―: Not available | |||||||

| Splash Guard (enclosure is optional) | Splash guard | Splash guard + Rear splash guard | |||||

| Coolant unit | Paper filter type / magnet separator 240ℓ (OP) | ||||||

| Magnet chuck | Permanent electromagnetic chuck | ||||||

| Chuck controller | ● | ||||||

| Vertical feed (Y) and cross feed (Z) pulser handwheels | ● | ||||||

| Longitudinal feed (X) handwheel | ● | ||||||

| Wheel axis inverter | ● | ||||||

| Scale & indicator | Vertical axis (Y) & cross axis (Z) / 0.0001mm | ||||||

| Lubrication method | Automatic lubrication system with oil shortage detection | ||||||

| Single-point dresser ※1 | Dedicated for external parallel dressing type (※1 only with table dress) | ||||||

| High speed reciprocating function | ● | ● | ― | ― | ― | ||

| Standard grinding function | |||||||

| Surface grinding (incl. surface within groove) | ● | ||||||

| Groove grinding | ● | ||||||

| Program grinding (surface + groove) | ● | ||||||

| Contour grinding | ● | ||||||

| Dressing devices (optional) | |||||||

| Rotary dresser (single disc) | ■ | ||||||

| Rotary dresser (two discs) | ― | ■ | ■ | ■ | ■ | ||

●: Standard equipment ■: Optional ―: Not available

The contents are subject to change without notice.